|

|

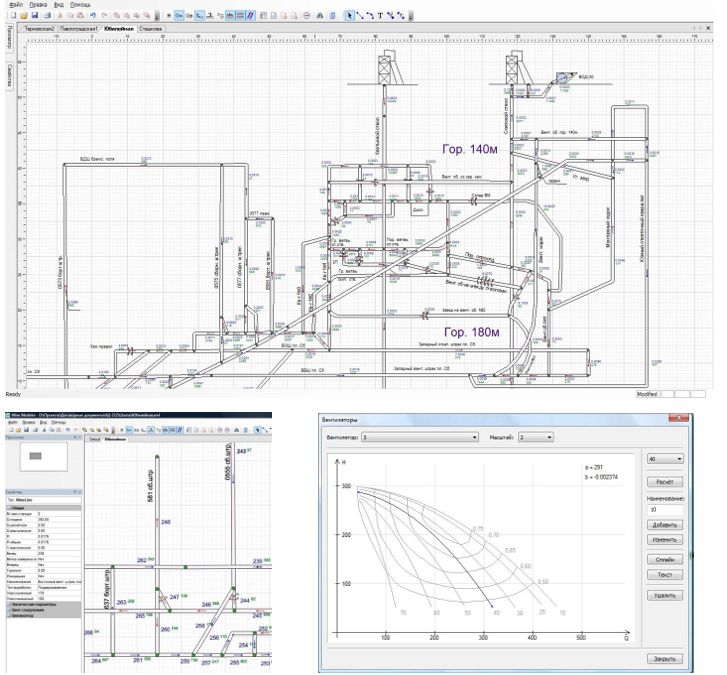

Mine Modeler

Modern mining enterprises have a large extent of mining operations and often exploit the deposit in complex mining and geological conditions. With the increase in the depth of minerals development, the emission of poisonous and hazardous gases is increasing, and the temperature of the air increases, which entails a deterioration of control and management of air distributions in galleries. This, in turn, causes the consumption of a huge amount of electricity consumed by main fans of mines. In percentage terms, it reaches about 40% of the total costs of the company, which is 3 - 5 million UAH per year. The provision of underground workings of coal mines with the necessary air flow is one of the main tasks regularly solved by engineering and technical workers of DTEK. DTEK is the energy sector of System Capital Management, the largest business group in Ukraine that represents the vertical integration of enterprises that create a production chain from coal mining and coal preparation to electricity generation and distribution. The complexity of DTEK�s mine ventilation net, their branching, non-linearity of the equations describing the movement of air in mining, make it almost impossible to optimally solve the problem of air distribution without the use of computers. Today, modern programming languages allow the creation of simulation models for the distribution of air underground mining enterprises. One of these systems is the �MineModeler� software. It provides a solution to the complex of air distribution tasks in the mine ventilation network and is oriented for the work of specialists in the areas of ventilation and depression services. The basic data set for the �MineModeler� program is the aerodynamic resistance of the ventilation structures and branches, their interconnections and the characteristics of the traction sources. The main advantages of �MineModeler� include the following: - an intuitive interface that creates comfortable working conditions, as well as ease of training and program management; - the efficiency of making changes in the scheme of mine ventilation network and the accuracy of calculations; - visual representation of the places of overflow of the ventilation flow during the simulation of emergency situations; - compatibility with a number of software tools (Revod 4.0, AutoCAD, Microsoft Word, Microsoft Excel); - maximizing the full use of the capabilities of modern computer equipment and modern operating systems; - possibility of unlimited functionality increase; - the use of modern software development tools. Implementation of the project on the improvement of ventilation systems was carried out at 6 mines of DTEK Pavlohradvuhillia. For their conditions, the simulation models of air distribution have been constructed, which allowed to simulate the ventilation system not only in the laboratory conditions of the developer but also at the enterprises and to develop solutions for the improvement of ventilation systems. In particular, the future of ventilation for the new development and working faces was simulated and the future development of mining work on ventilation issues for 3-4 years ahead. During the experimental exploitation of the software, the average absolute error of the actual and estimated air volume did not exceed 15%.

Participation in scientific and technical meetings has shown that DTEK is interested in implementing the project �VirtualMine: as a modeling tool for Wider Society Learning�, which is being implemented within the framework of the European Horizont-2020 program and is ready to consider introducing them into their business. |